TRUEDEK® Steel Formwork

TRUEDEK® is a permanent steel suspended slab formwork system that provides significantly more features - and a number of additional benefits compared to existing steel formwork and metal decking systems.

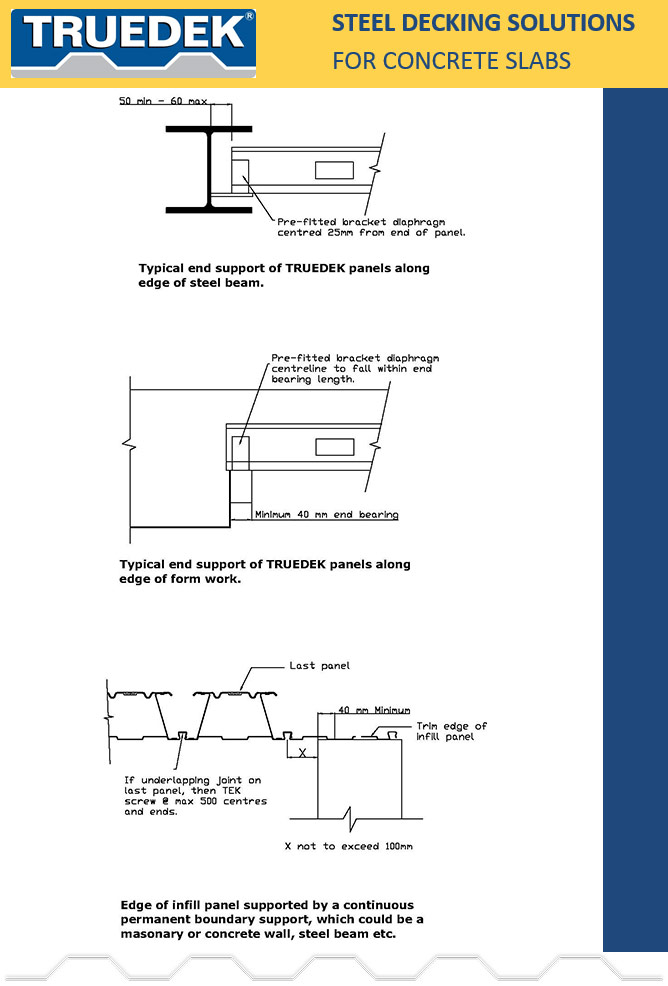

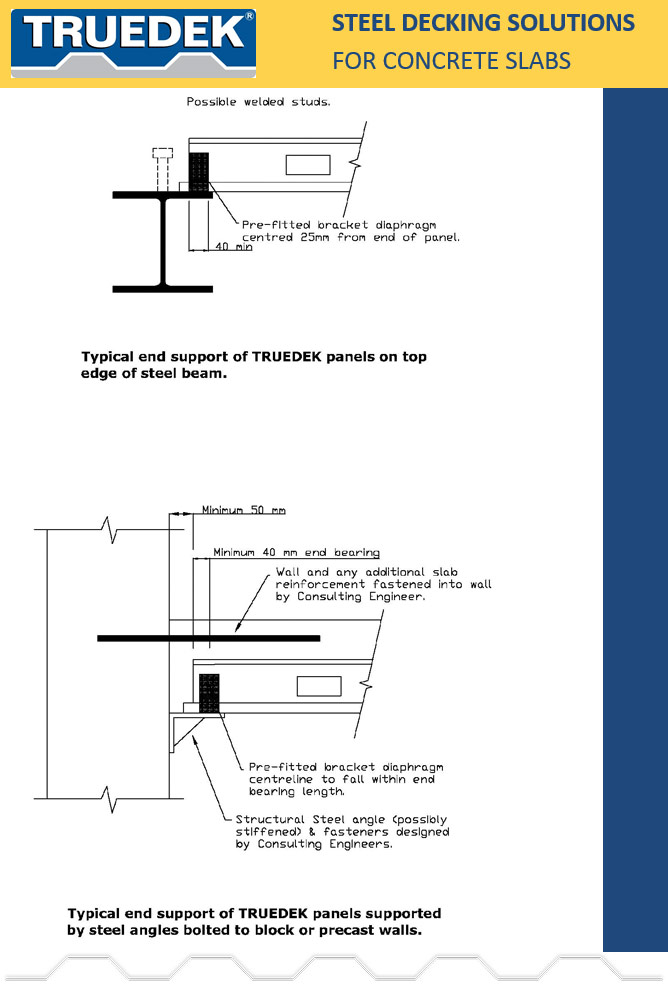

Installation: Download your Installation Guide, including pre-start needs, detailing requirements, safety instructions and installation procedures for all configurations.

Technical Design Manual: Detailed information on design principles and configurations for Engineers, Architects and Specifiers.

TRUEDEK® Design Software: TRUEDEK® Design Software for Engineers, Architects and Specifiers. Please click this link to download the TRUEDEK® Design Software Installer File.

Brochure: Get a brochure to learn more about the advantages of this revolutionary suspended slab formwork.

Presentation: Need to show someone that TRUEDEK® is the best permanent formwork system for their project? Click here to see 'PDF Presentation'. (Download 4MB)

Design Quick-Guide

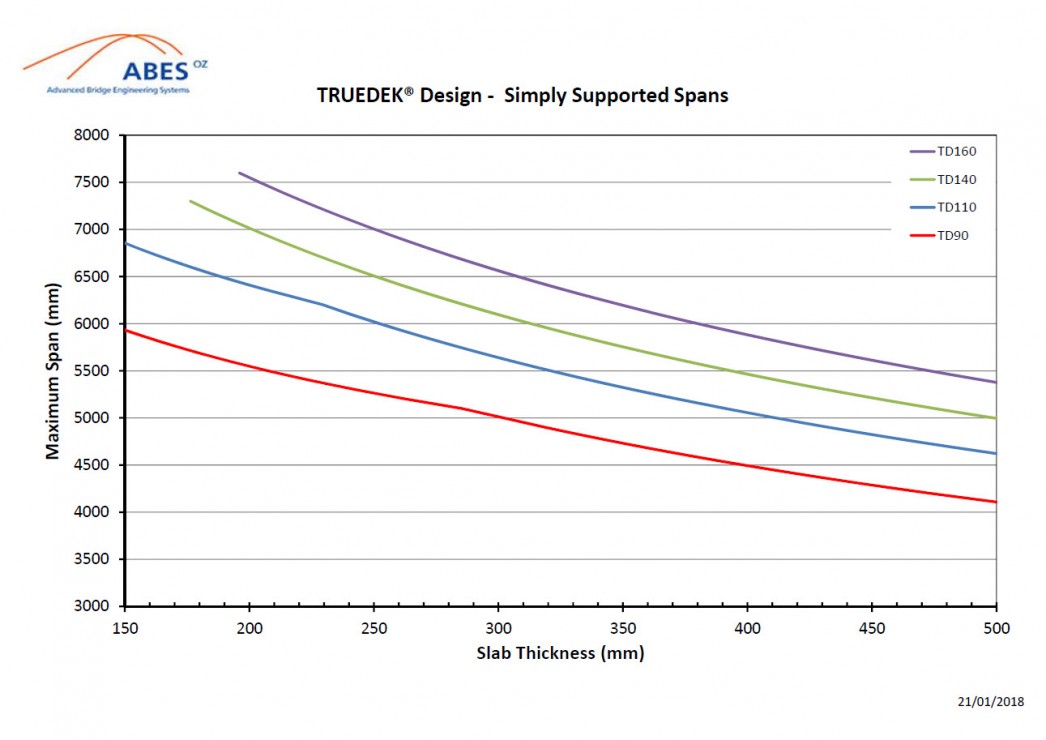

TRUEDEK® is built to specification and can be tailored for particular slab design, fire rating, deflection and serviceability requirements, while spanning lengths of over 7 metres unpropped.

Design and detailing should be carried out by a qualified Structural Engineer. For detailed technical information, download the TRUEDEK® technical design manual.

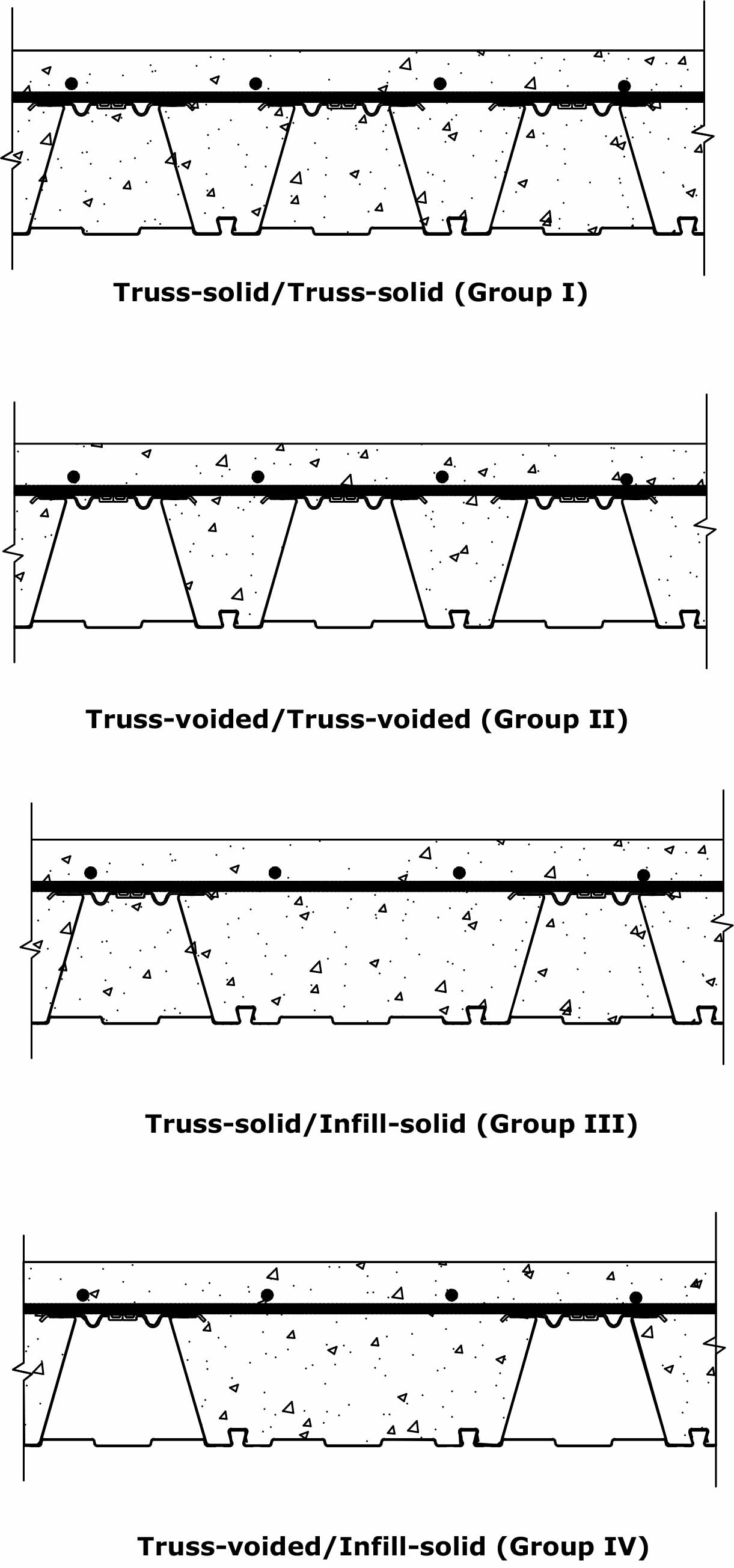

Available configurations include voided, partially voided and solid - each of which brings different benefits across a range of criteria.

Fire Rating: Composite TRUEDEK® slabs can be designed for a fire resistance level (FRL). This level of resistance is dependent on the placement of additional fire reinforcement.

Deflection: The effect of wet concrete on the deflection of the TRUEDEK® panels is negligible when calculating the cubic metres of concrete required, as they are pre–cambered upward to eliminate wet concrete deflection preventing concrete ponding and creating truly flat soffits.

Services: With the soffit of the TRUEDEK® being smooth the installation of services such as cabling and fire sprinkler pipes is much easier as there are no set-downs or beams to install around. TRUEDEK® also speeds internal wall framing as all metal framing studs can be cut to an identical height. Small services can be run through the deck at time of installation and other penetrations through the finished slab can be done via core drilling or by blocking out penetration prior to concrete pour.

For more information on the benefits of different arrangements, including detailed processes for all configurations, download the TRUEDEK® design manual or contact us today.

For more information on installation procedures, including safety, worksite and labour requirements, download the TRUEDEK® installation guide.